Please note that this website is being maintained by Prof. Felix Beck to preserve and document the work of the team of researchers that were involved in NYUAD’s Plastic Lab from 2018–2021. Even if the lab continues to exist, there will be no new projects featured on this website. For further information about the recent work of the Plastic Lab reach out to Khulood Alawadi.

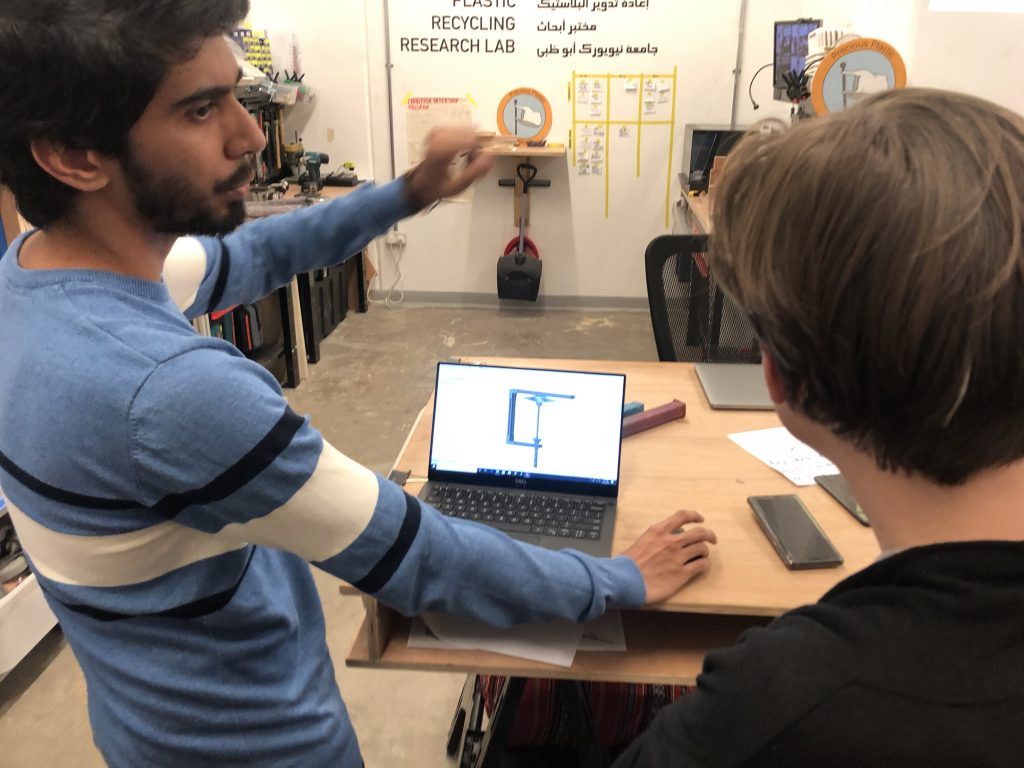

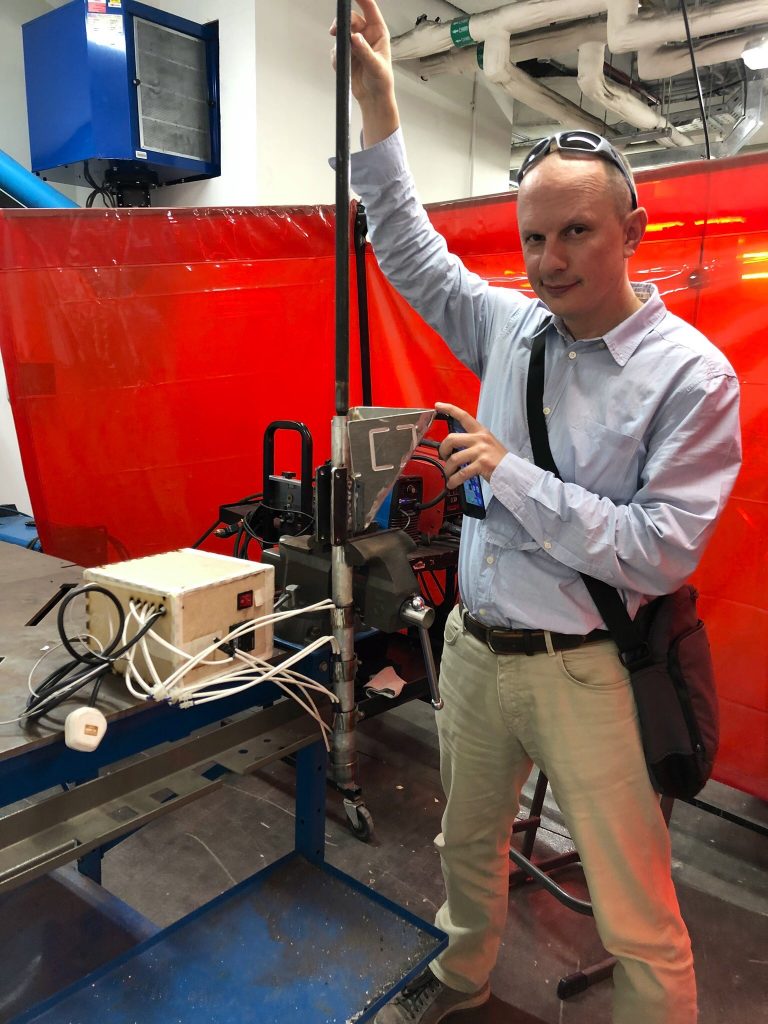

Design of a plastic injection machine – Engineering Capstone project 2020

The three engineering students Kazi Owais Ahmed (Mechanical Engineering), Muhammad Rafay Ashfaq (Electrical Engineering) and Hamza Haider (Electrical Engineering) worked on their new design for a plastic injection machine.

The goal of the group project was to further develop the mechanical and electrical engineering aspects of the Precious Plastic injection machine V02 which enables users to manually inject melted plastic into a mold to create plastic objects. For this capstone project, the group implemented features like a touch screen with integrated user interface to access and control the movement of an integrated electric screw jack. This system enables the user to operate a piston handsfree. A new heating system was successfully designed and implemented. The blueprints and schematics will be published on this website – stay tuned!

Thank you!

Introduction to the Plastic Lab (360 video)

Visiting Undergraduate Research Program

We are happy to announce that the Plastic Lab was able to secure the funding for the position of a Visiting Student Research Assistant for summer 2020!

The goal of this summer research project is to deeply dive into the pathways of plastic and plastic waste throughout the UAE and to map those into an understandable flow-chart diagram. The result will help to analyze the streams of waste, from for example personal or industrial cause to recycling plants or landfills, and to understand the related processes. A second responsibility of the summer researcher is the development of a workflow for the use of the newly installed plastic extruding machine, and to integrate the machine into the weekly procedures of the lab’s Student Research Assistants. The goal is to create a flow-chart diagram for the process of creating plastic beams and parts that can be used to make furniture.

The deadline for applications is March 30. Please email nyuad.undergraduateresearch@nyu.edu with any questions.

Findings of HDPE Plastics in Heat Compression Machine

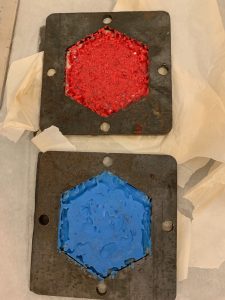

Using the heat compression machine, we are able to make rather elementary shapes, like hexagons. This is probably the most common Precious Plastics first project because of its relative simplicity. However, we have been testing it out with different colors, brands, and plastic types. Outlined below we have our process, findings, and future avenues of inquiry.

(Our heat compression machine)

Our process:

- Place paper sheet below (for preventive measures)

- Place solid metal plate (filled fully)

- Stack another solid metal hexagon mold plate

- Add 115 ml of whichever color, number 2 plastic (HDPE) into the mold

- Place paper sheet on top

- At 275 ºC for 15 minutes, heat the mold

- At the end, take the molds out, place another solid metal plate on top (this prevents the piece from puffing out, as it usually does), and let cool for 10 minutes

- Flip the molds (they will most likely not be full at the edges, like the photo below), so fill the edges with about 30 ml of the same color of HDPE

- Place back into the heating machine for another 7.5 minutes (remember to place a paper sheet on top of it!)

- Take it out and place the metal sheet on top of it to prevent puffing, waiting about another 10 minutes

- Paper will most likely stick to it, but you can take it off with water

Our results:

(Before adding the 30 ml of extra plastic)

(The final result. Notice that the one on the left has a more even color distribution as compared to the other side, pictured on the left)

Current findings:

Surprisingly, different colors react differently. This may be because our blue shredded plastic material was mainly comprised of blue Al Ain bottle caps while the red was a conglomerate of different brands. This, we will have to explore in future tests, when considering brands and purity of the plastic used, since some brands may have different manufacturing processes.

Additionally, the top side (before being flipped) tends to not melt evenly; instead, it maintains its speckled design, perhaps making it more interesting than its other side where it more evenly distributes after the second heating. We need to experiment more with these, especially when considering color fusion in future designs.

Finally the use of paper on top of the plastic while it heats seems to add a wavy texture to the melted plastic, most likely due to its expansion during heating and retraction during cooling. Manipulation of the quality of these plastics could lead to more interesting textures in the design of such simplistic shapes.

Future avenues of inquiry:

While there are many different aspects we still have yet to explore, we need to test the characteristics of the plastic within different colors, even becoming more specific to brands, to see if that makes a difference. Beyond this, we would like to explore how color mixing would change the process. Additionally, we need to see how heating the bottom plate (because the bottom plate is not also heated) would affect the overall distibution of color, rather than maintaining a speckled design.

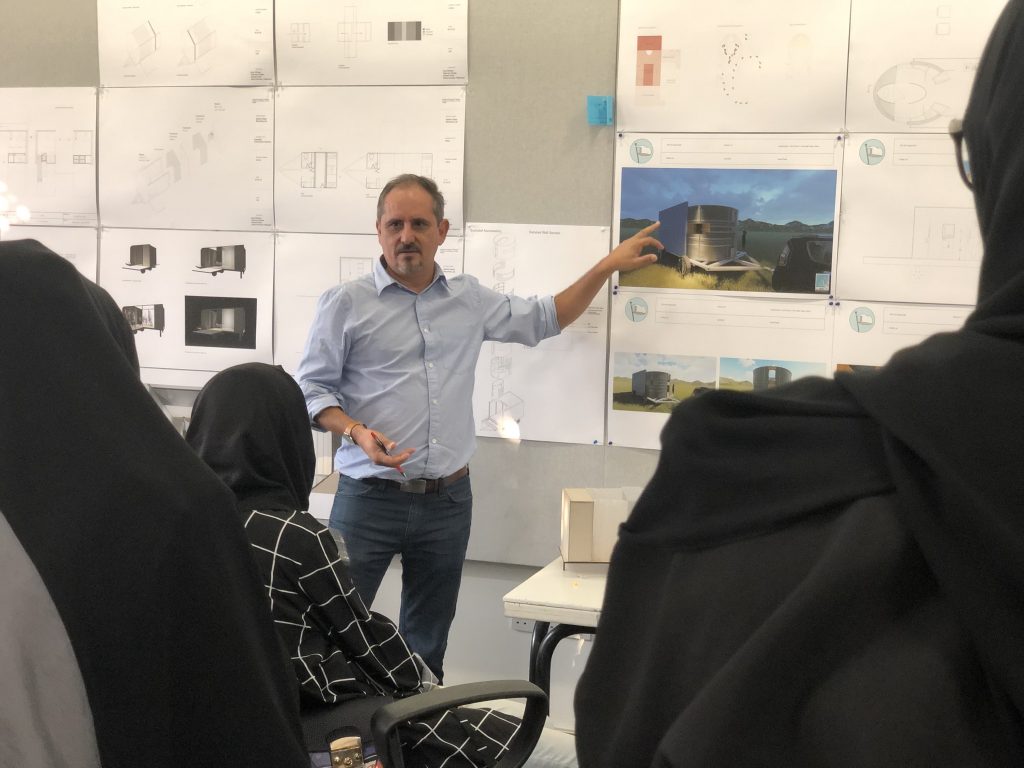

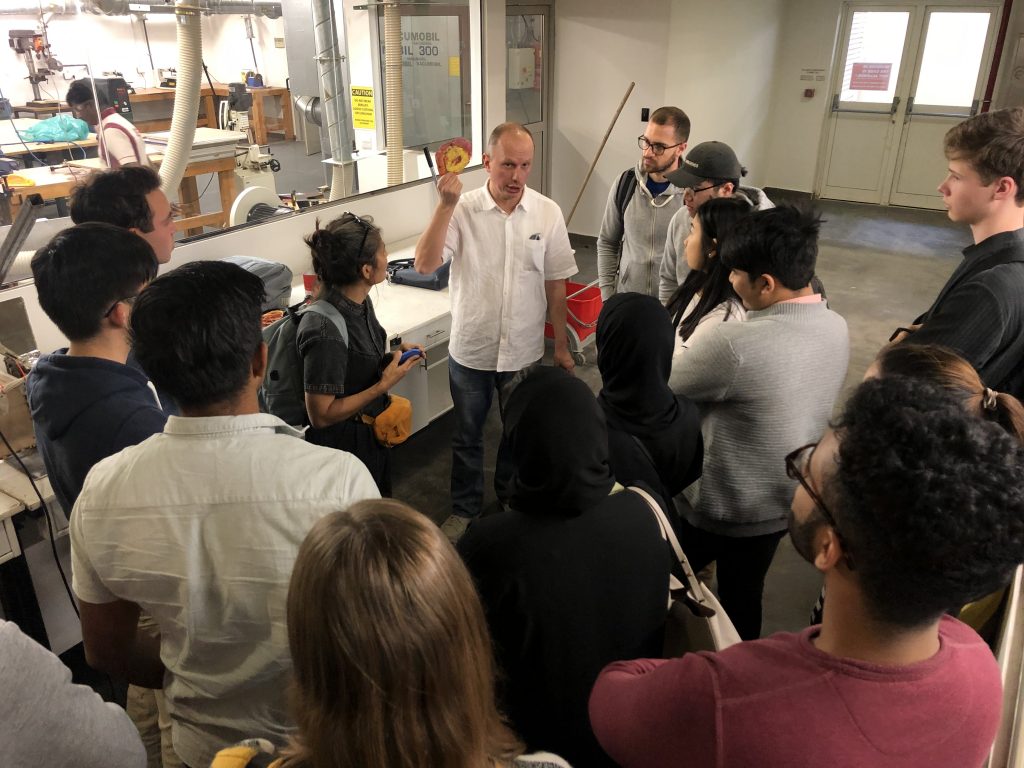

New course ‘Plastic Fantastic !?’ offered during J-Term

What would a world without plastic look like? How does the world look because of it? The newly offered course Plastic Fantastic !? looks critically at plastic’s ubiquity in global consumer cultures. (Find the course syllabus here.) Students will consider plastic’s predecessors and contemporary alternatives and engage with a range of topics, from the environmental politics of plastic debris in oceans, to the ethics and values of plastic surgery, to the proliferation of cheap plastic toys and fashion trends. Based on these discussions, and inspired by the original meaning of the Greek term plastikos (to grow, to form), the class will develop and create a product using recycled plastic waste in NYUAD’s Plastic Recycling Research Lab. In addition to the completed project, to be displayed in an exhibition at the January Term’s end, students will leave with a personal philosophy of Art, Design, and Technology as well as a sense of how mutually reinforcing and beneficiary a mix of these fields can be for future problem solving. Mandatory field-trips include visits to relevant industries (water, oil, waste, etc.), natural reserves, and landfill sites in the UAE and the Philippines (Manila).

El Nido – A little corner of (sustainable) paradise

With more than 7,000 thousand islands to choose from, one would expect it to be hard to find the best places to visit in the Philippines. Yet, when it comes to recommendations, El Nido tops all the lists on the internet as the ‘best’ and ‘most beautiful’, and is one of those rare occasions, the hype and fame are all well-deserved in the case for this little corner of paradise.

With more than 7,000 thousand islands to choose from, one would expect it to be hard to find the best places to visit in the Philippines. Yet, when it comes to recommendations, El Nido tops all the lists on the internet as the ‘best’ and ‘most beautiful’, and is one of those rare occasions, the hype and fame are all well-deserved in the case for this little corner of paradise.

However, the reason for writing about this breathtaking place is not just to praise its beauty, but also to appreciate the local efforts to keep this scenery intact with sustainability in mind. The place is still in development, per se, despite its overwhelming popularity, but unlike most cases where the sudden surge of tourists overwhelmed the area and concluded in mother nature being the victim of harmful tourism, El Nido is consciously trying to develop and better their services without destroying the very thing that caused the place’s popularity, its pure and untouched natural beauty.

Its most popular tourist activities, the island hopping tours around the smaller islands surrounding El Nido begin with each visitor paying a small fee for a life-long environment tax to (literally) pay their respect for mother nature – as long as they save the paper of the tax being paid, which you are reminded of every time by all tour guides and tourist offices). “Sustainability and environment mindedness is a conscious action by all in El Nido,” says every captain at the beginning of the day tours around the islands. Every tour includes a quick training on environmental consciousness. No littering on the islands is allowed, and if anyone spots any trash, they are reminded to kindly pick them up and give them to the boat staff so that every new visitor of the islands will feel like they are the first ones to ever set foot on the place.

Its most popular tourist activities, the island hopping tours around the smaller islands surrounding El Nido begin with each visitor paying a small fee for a life-long environment tax to (literally) pay their respect for mother nature – as long as they save the paper of the tax being paid, which you are reminded of every time by all tour guides and tourist offices). “Sustainability and environment mindedness is a conscious action by all in El Nido,” says every captain at the beginning of the day tours around the islands. Every tour includes a quick training on environmental consciousness. No littering on the islands is allowed, and if anyone spots any trash, they are reminded to kindly pick them up and give them to the boat staff so that every new visitor of the islands will feel like they are the first ones to ever set foot on the place.

Plastic straws? Almost non-existent. It’s harder to find a bar or street vendor with plastic straws then it is to avoid one here. Sea vendors who approach the boat tour participants during island hopping only have bamboo straws and the few private beaches that have shopping huts for refreshments either use the same bamboo straws or cut the bucos (coconuts) in a shape so that you can enjoy it straight from the shell without spillage or littering (excluding the shells themselves… but they are part of nature so the only thing they might destroy is the aesthetics of a clean beach). Or if not bamboo straws, most restaurants use metal straws to serve their refreshments in the towns.

Plastic straws? Almost non-existent. It’s harder to find a bar or street vendor with plastic straws then it is to avoid one here. Sea vendors who approach the boat tour participants during island hopping only have bamboo straws and the few private beaches that have shopping huts for refreshments either use the same bamboo straws or cut the bucos (coconuts) in a shape so that you can enjoy it straight from the shell without spillage or littering (excluding the shells themselves… but they are part of nature so the only thing they might destroy is the aesthetics of a clean beach). Or if not bamboo straws, most restaurants use metal straws to serve their refreshments in the towns.

With their effort and hard work, the people of El Nido are a great example of how to develop sustainable tourism to appreciate and show off the best side of mother nature. There’s still room for improvement as the place will develop, but they are taking the right steps towards a better and more sustainable way of tourism.

With their effort and hard work, the people of El Nido are a great example of how to develop sustainable tourism to appreciate and show off the best side of mother nature. There’s still room for improvement as the place will develop, but they are taking the right steps towards a better and more sustainable way of tourism.

Press Release (New York City, April 5) – Precious Plastic: Mobilizing Plastic Recycling

| Precious Plastic NYUAD Presentation | New York City, USA | April 5 |

On April 5, one of our members of Precious Plastic NYUAD gave a presentation, titled Precious Plastic: Mobilizing Plastic Recycling during the Global Engagement Symposium at NYU’s New York Campus.

During his 20-minute presentation, Hamza Haider talked about his summer internship experience in Sarajevo where he helped found the Precious Plastic Sarajevo LAB as well as his involvement with Precious Plastic NYUAD, here in Abu Dhabi. In his speech, he mainly focused on the procedures involved in the two initiatives that serve the same purpose yet are at stark contrast to each other in the manner of their progress and audience.

Thanks to Hamza, many more people were informed of the work we do worldwide within the Precious Plastic community, and hopefully, with more opportunities like this, we will be able to grow bigger and greater to spread the positive message of plastic consciousness.

Importance of Accountability in Plastic Pollution Crisis

Accountability can reverse plastic pollution crisis, says WWF report.

On March 5, 2019, WWF released a report titled “Solving Plastic Pollution Through Accountability”. The report was released before the key meeting of the United Nations Environment Assembly (UNEA) that will take place next week in Nairobi.

The new study warns us that an additional 104 million metric tons of plastic is at the risk of infiltrating our ecosystem if business as usual continues, with overall CO2 emissions increasing by 50% by 2030 from the plastic life cycle.

The ever-increasing leakage of plastic into our nature have serious consequences for our wildlife, our ecosystem and us, humans alike. The system as a whole needs to take responsibility for the true cost of plastic production, especially for their effect on nature and the people. We are only beginning to understand what plastic consumption does to people, yet every year we continue to ingest plastics from food and drinking water.

Our methods of producing, using and disposing of plastic is fundamentally broken, and the system lacks accountability. Focus has been put mostly on consumers and waste management while the rest of the plastics value chain were ignored in the conversations.

Public outrage and concern for the plastic crisis is growing, along with the demand that governments and business show take decisive actions to reduce plastic waste. The issue can only be solved efficiently and effectively if we enforce the right level of accountability across the whole plastic supply and value chain.

We already know solutions to the crisis – from reduction to collection, from recycling to use of alternatives. Reinforcing existing initiatives such as the elimination of single-use plastics, upgrading national waste management plans and reaching 100% collection rates can all help stop the global plastics pollution crisis from getting further out of hand before its too late.

If system-wide accountability is implemented and exercised effectively, the crisis can be resolved with the next generation’s time. This is the time for action!